First Chilean Odor Emissions Standard: a challenge for the pig sector

On February 6, 2023, the first Chilean environmental standard for odor emissions in the pig sector came into force. This is the first standard issued as part of the Odor Management Strategy implemented by the Chilean Ministry of the Environment since 2014. The odor standard seeks to prevent and control emissions from pig farms -an […]

On February 6, 2023, the first Chilean environmental standard for odor emissions in the pig sector came into force. This is the first standard issued as part of the Odor Management Strategy implemented by the Chilean Ministry of the Environment since 2014.

The odor standard seeks to prevent and control emissions from pig farms -an issue on which the industry has already made progress- by laying down technological improvements to reduce emissions from the source. It will be applied country-wide for pig farms with more than 750 animals. Both control and oversight will be conducted by the Superintendence of the Environment.

Daniela Caimanque, Head of Odor at the Ministry’s Noise, Light, and Odor Department explains: “Based on the diagnosis conducted by the Ministry for drafting this regulation, we know that there are significant differences between small and large farms in Chile. This is why the regulation establishes requirements focused on reaching ‘technological baselines’ according to farm size. Small farms must cut emissions in the lagoons; medium-sized farms, in both lagoons and composting areas, while existing large farms (P95) -that have already applied these measures- are required to go one step further and reduce emissions to 8 European odor units per square meter. This requires reductions in other areas and, in many cases, implementing additional measures to the technologies already implemented.”

Daniela Álvarez, ChileCarne’s Sustainability Manager underscores: “The standard is one of the strictest worldwide, which is good news for many, but it also means significant efforts for a fragmented sector made of 80% of small and medium-sized producers that face the challenge of feeding a growing population with high quality sustainable products at affordable prices. The new requirements mandate reducing odor emissions in existing farms and impose stricter caps for new farms.”

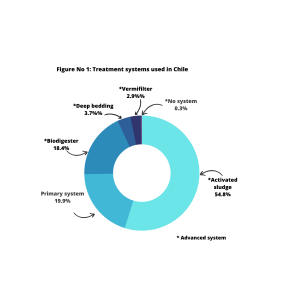

Since 1999, the Chilean pig sector has been working to control odor emissions at farms by implementing clean production measures and practices. At the same time, it has invested in cutting edge technology for slurry management, which is the main source of unpleasant odors at farms. Currently, 80% of production uses advanced slurry treatment systems such as activated sludge, biodigesters, vermifilters, deep bedding, and solid waste biostabilization, reducing odor emissions up to 95% at the farms.

Daniela Caimanque adds: “The regulations focus on technology. Therefore, implementing both technology and best operational practices plays a relevant role. If odor abatement technologies are not properly operated and maintained at the pig farm, they will not produce the expected mitigating effect. This is why, when implementing the regulations, we will monitor odor abatement technologies and avoid odor and nuisance episodes that impact neighboring communities.”

“The progress the industry has already made with the support of the public sector is complemented by the efforts led by the Chilean Meat Exporters’ Association, ChileCarne, together with the Pork Producers Trade Association, Asprocer since 2018, when they joined the Ministry of Agriculture’s Chile Conscious Origin Program. The program provided us with the first sustainability standard for Chilean pig production and considers 17 aspects of sustainability, including: water and energy efficiency, carbon footprint measurement, community outreach, odor nuisance management, and support for producers in the adoption and implementation of these regulations via technical assistance and training. To date, more than 130 facilities have joined the program and are close to being certified, and we hope to move forward this year by adding more producers to this initiative that promotes a competitive and sustainable agri-food sector in both local and international markets,” Álvarez points out.

According to studies conducted by Asprocer, the cost for companies of implementing the standard would reach 82 million USD. The association has designed a strategy to support compliance based on four pillars: collaboration with officials and technology and service providers; training for companies and staff; technical assistance; and support for community outreach on the implications of this regulation, as well as the changes and progress made by the companies.